Sometimes customers come to us with beautifully complex ideas, designs based on special locations they have been to, or elements that have been calling to them. We love the art form of mokume and its vast possibilities in both palette and pattern. Arn especially loves to make exquisitely custom and exploratory work that would be impossible to recreate, making the ring even fully of an object d’ art. When the visions our clients have in mind for their rings fall outside of our stocked palette and pattern options, we create custom billets. This is an opportunity to personalize the design even further to their individual tastes.

The Billet

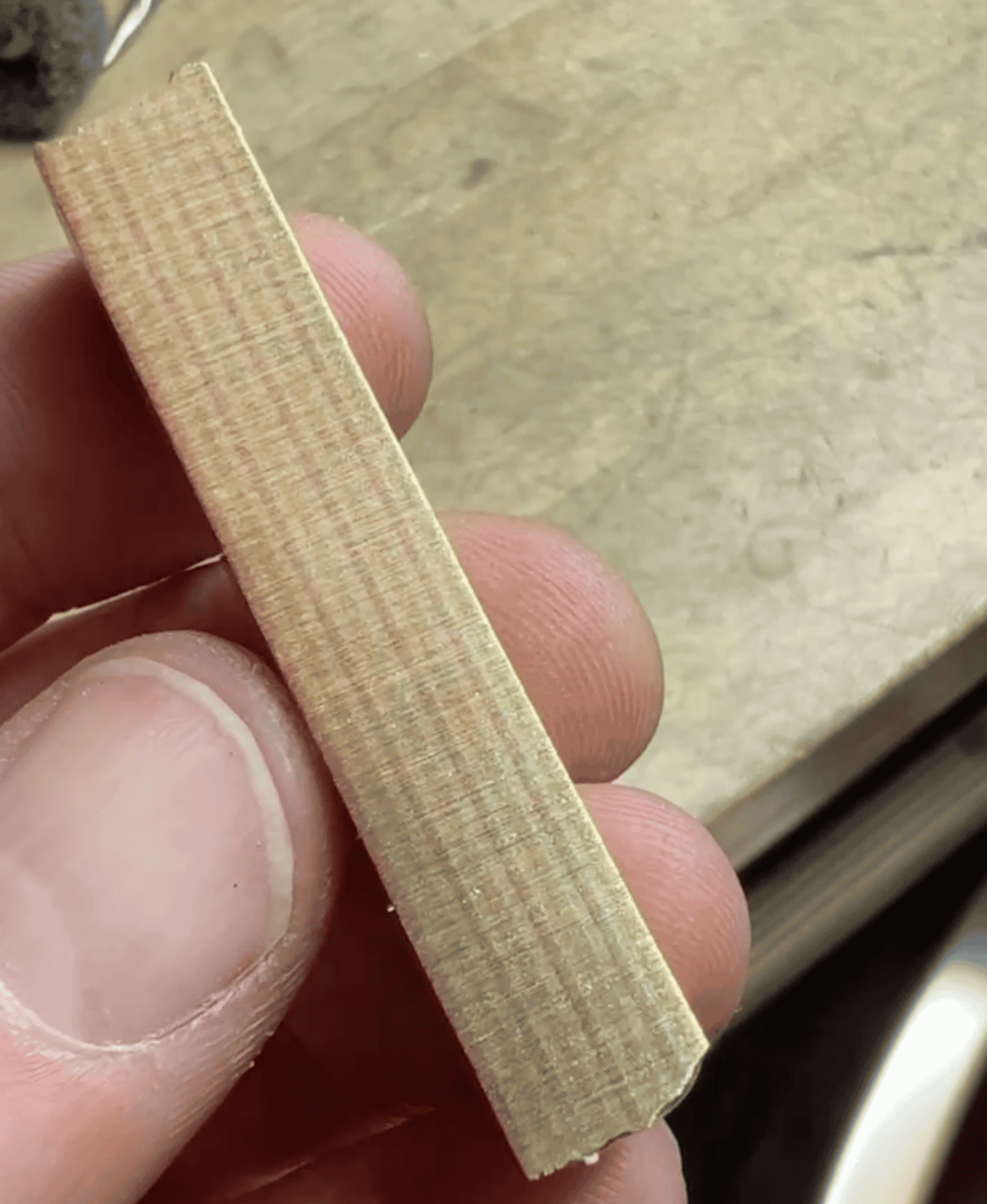

What’s a billet? A billet is the material that we create to make the rings from. It is layered precious metals bonded by a meticulous process of heat and pressure. Some makers of mokume purchase mokume billets from an outside source, but we make them from scratch, which allows for the greatest range of custom options. The sky’s the limit and our craft inhabits the highest realm of making.

Why Custom?

Mokume by nature is inherently wild, we find this is key to the beauty of this art form, no two rings are ever going to be exactly alike, by both the nature of handmade work and of mokume gane itself.

With this in mind, variations in the appearance of our designs are to be expected, especially with the color palettes. So many elements affect this, of course the patterns, but also the size and width of the ring. For clients with a strong preference regarding the look of the colors (which metal color or type is most dominant in the rings, the thicknesses of the various layers), a custom billet can be a great option.

Custom billets do come with added cost and sometimes wait time, and we wanted to take you through the process to show the diligent and detailed work that goes into them. Each custom billet is assembled from scratch and created specifically to order.

The Process

We thought we might explain the process of making the custom billet so that our clients can see what goes into this endeavor.

1. Determining and ordering the metals – this begins during the design consultation process, choosing the metals and proportions, and then special ordering the necessary material.

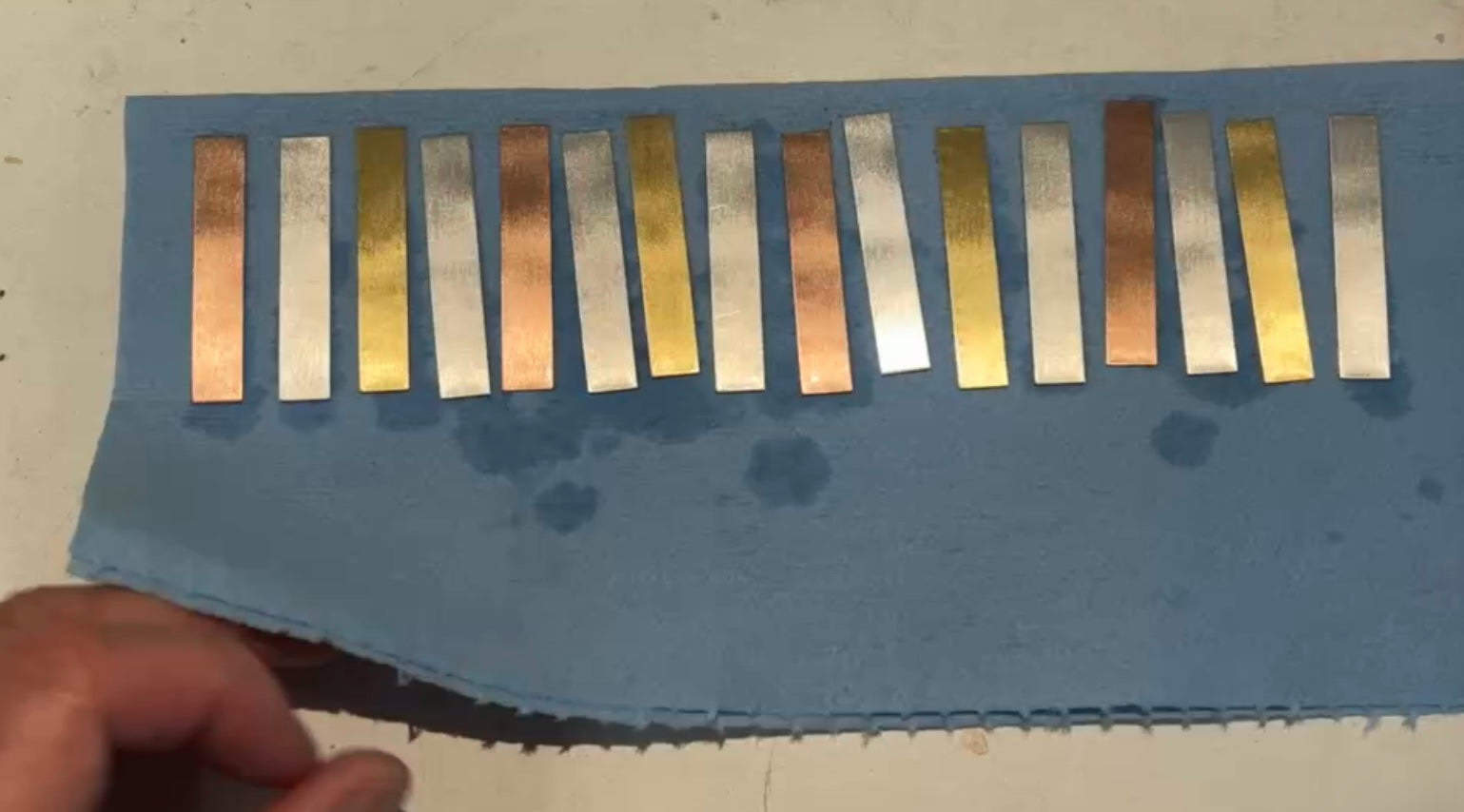

2. Cutting the metal sheets to size – the metals arrive in thin sheets, and are cut down to the correct measurements to be made into a billet.

3. Cleaning the sheets – each piece of metal is carefully cleaned (this is essential for bonding the metals).

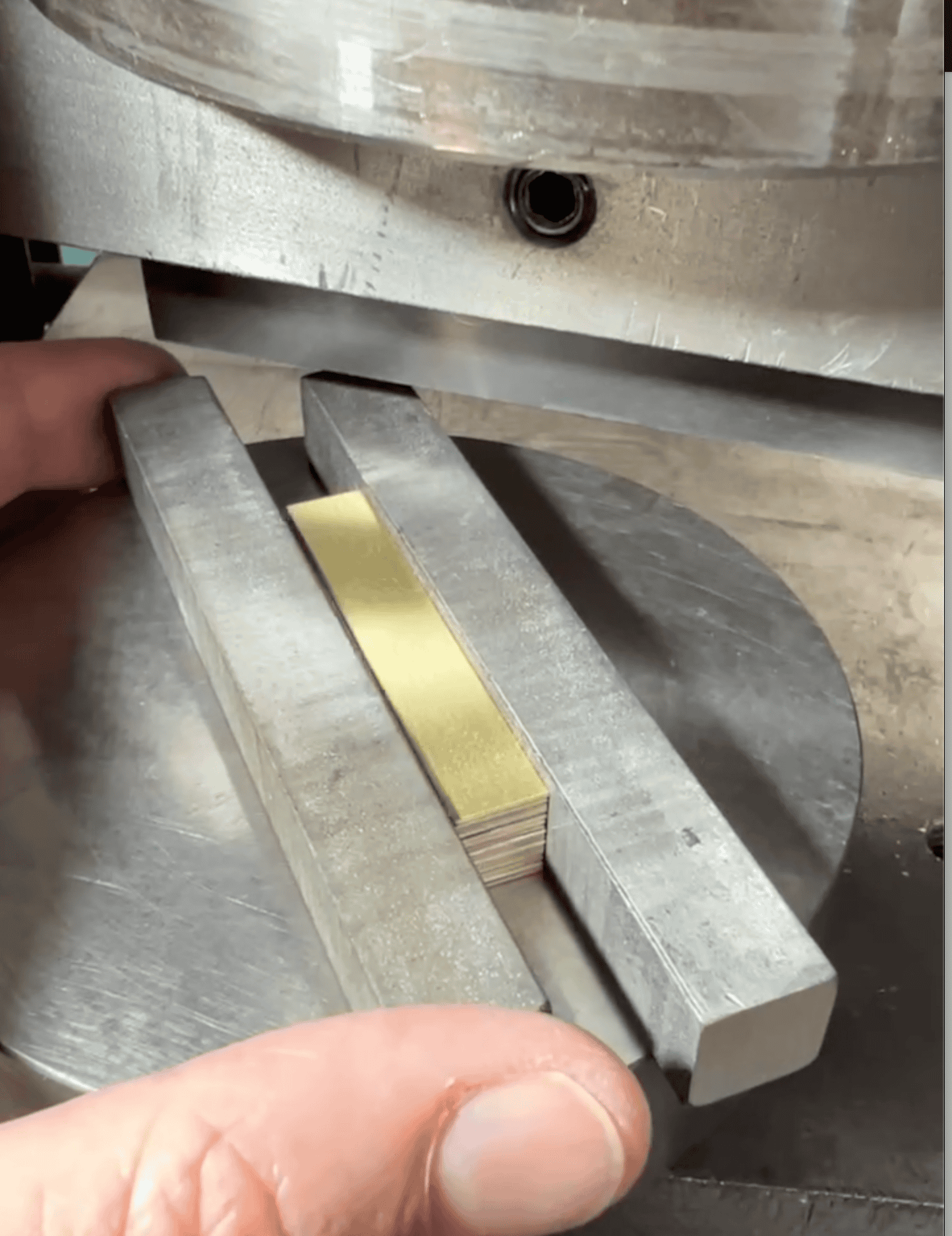

4. Pressing the billet – the sheets are stacked and pressed with the hydraulic press to create an initial bond.

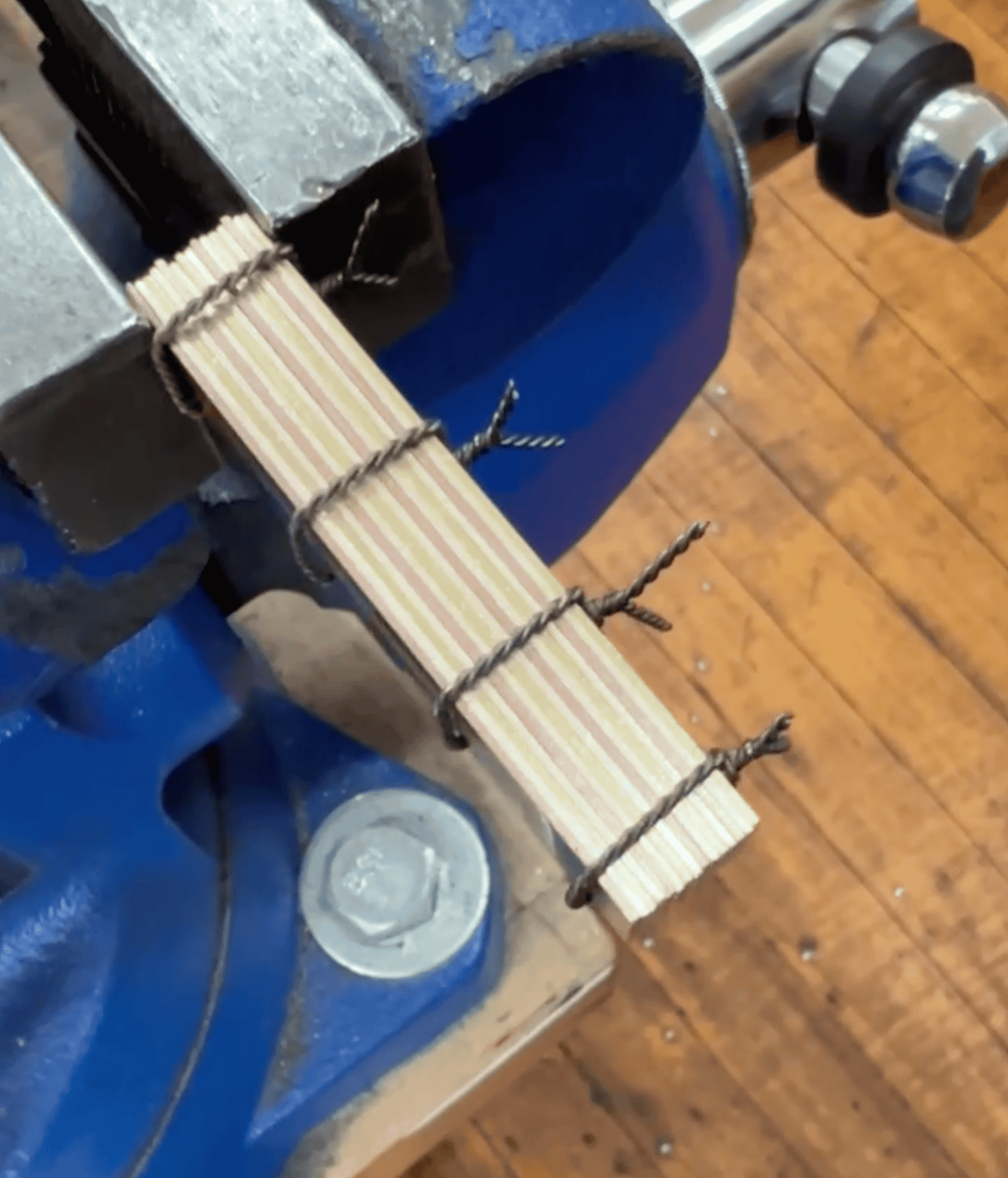

5. Binding the billet – the billet is held together with binding wire to keep everything in place while firing.

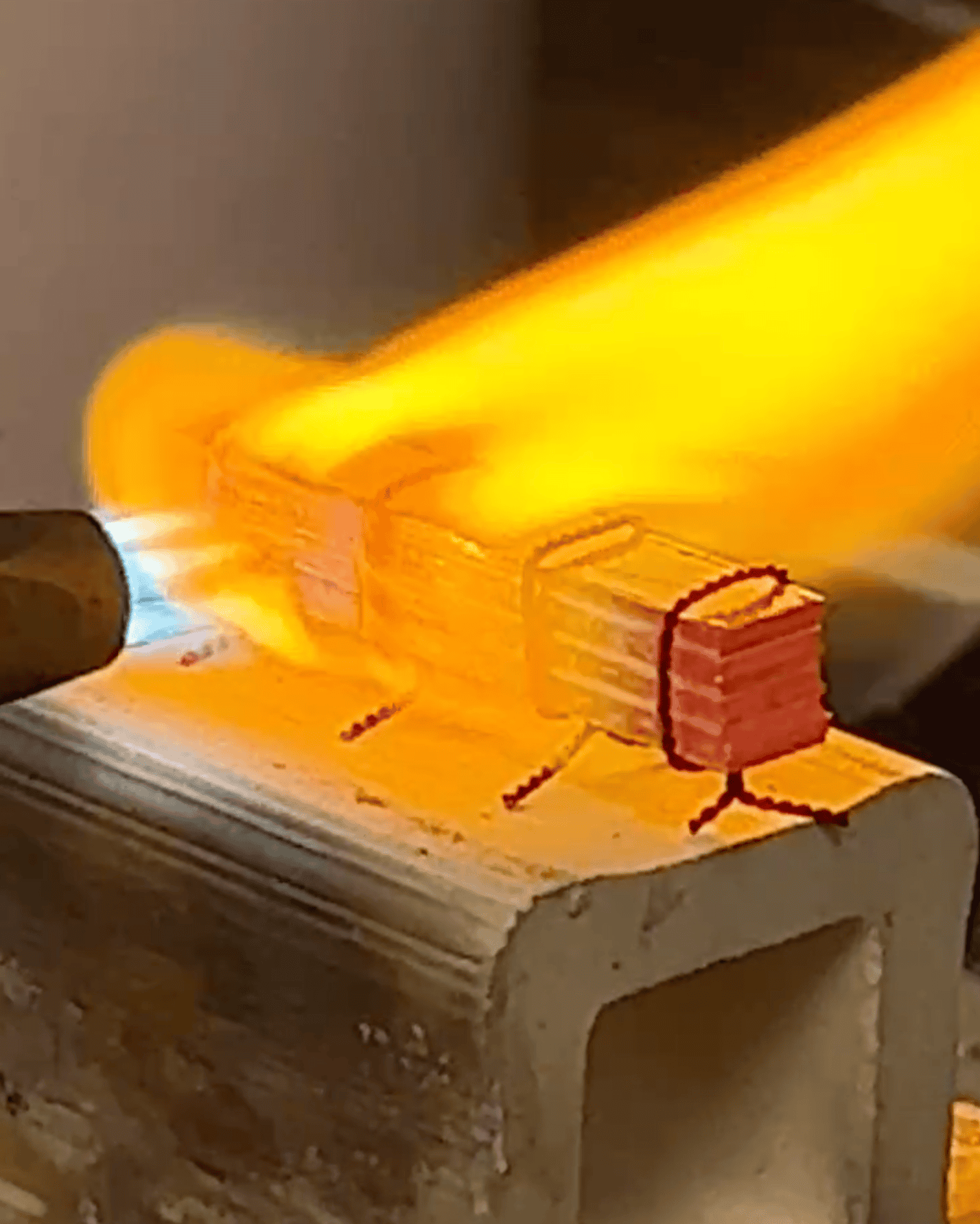

6. Firing the billet – the billet is either torched or fired in the kiln.

7. Hot pressing the billet – straight from firing, still hot, the billet is pressed again in the hydraulic press.

8. Trimming the billet – the very edges of the billet are trimmed off to make everything perfectly square again.

9. Rolling and forging the billet to stock dimensions – the billet is gradually worked and shaped down to ring stock (it starts to resemble a long stick rather than a brick) so it’s at the correct dimensions to be made into a ring!

Making custom mokume pieces is always a labor intensive and demanding process, but we truly love the work and the opportunity to share this amazing craft with others.